易科讯aoi编程视频教程主要用于,想要学习易科讯aoi设备编程的工程师,以提高SMT工程师专业素养。以下是在线视频,如果希望保存到本地,页面尾部有百度云盘和阿里云盘的下载链接提供下载和存储。

另外还有易科讯aoi编程教程文字档的使用教程说明书请浏览https://zhunwen.net/ekt-aoi-jiaocheng.htm

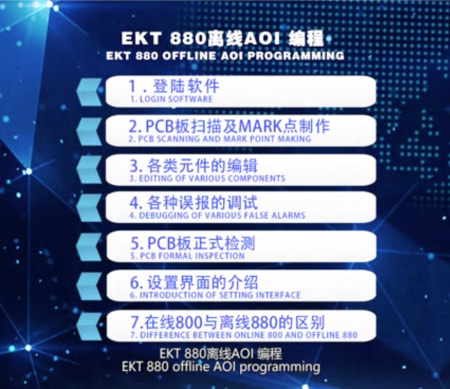

易科讯aoi编程视频教程

- 1.登陆软件EKT-880

- 2.PCB板扫描及Mark点制作

- 3.各类元件的编辑;

- 4.各种误报的调试;

- 5.PCB板正式检测;

- 6.设置界面的介绍;

- 7.在线800与离线880的区别。

以下内容是EKT-880离线AO编程视频字幕所对应的讲解内容,以供SMT工程师参考每段视频所讲解的内容。

1.登陆软件

1.LOGIN SOFTWARE

今天教大家如何制作离线机880的检测程序

Let’s go through how to make an inspection program for offline model 880。

首先打开A检测软件,中英文可切换

First open the AOl software,Chinese and English can be switched.

初始用户是A001,密码是123456

The initial user is A001 and the password is 123456.

登录后,系统提示是否回到原点

After logging in,the system prompts whether to return to the origin.

点击确定,轨道即回到原点,再点确认。

Click OK,the track will return to the origin,and then click OK.

提示是否打开上次使用过的程序,

System will then prompt whether to open the program you used last time.

如果需要选是不需要选否

If not,click NO

拧开轨道上两颗大圆螺丝,找一快目检良品放进去。

Unscrew the two large round screws on track,put a good PCB in.

将轨道宽度调至合适,然后拧紧螺丝

Adjust the track width to the proper position,then tighten screws.

把这两个夹子移到板上没有元器件的地方即可。

Move the two clips to the place where no components on the board.

2.PCB板扫描及mark点制作

2.PCB board scanning and mark points setting

做新程序时,打开工作模式里的新建模式

When making a new program,open the new mode in the working mode。

首先设置pcb板的尺寸大小,

First,set the size of the pcb board,

找到PCB板左下角,

Find the lower left corner of the PCB board,

点击这个原点,轨道会进去

Click this origin icon,the track will go in.

相机会自动移到pcb左下角,

The camera will automatically move to the lower left corner of pcb.

因PCB大小不同,要手动设置右上角。

Due to different PCB sizes,need to manually set the upper right corner.

可以点击这个界面上下左右箭头

You can click the up,down,left and right arrows

把相机线十字中心移到PCB右上角。

to move the cross center of camera line to the upper right corner of PCB.

点击屏幕左下方的“设定右上角点”,

Click “Set the upper right”button at the screen,

PCB的尺寸大小就会显现出来。

and the PCB size will appear.

然后点击“PCB板扫描”,输入PCB命名,

Then click “PCB Scan”,input the PCB name,

确定后机器会制作pcb缩略图

After confirming,the machine will make pcb image.

缩略图制作完成后,会提示设定mark点

After PCB image created,you are prompted to set mark point,

点确定即弹出mark点的设定界面。

And the mark point setting window will pop up.

在pcb板上选两个合适的mark点,

Select two suitable mark points on the pcb board,

通常我们会选择pcb板上的通孔

Usually we will choose the holes on the pcb board as marks.

首先把第1个通孔框起来,点设定,

First page the first hole,set it,

然后调整亮度和对比度,直至清楚

And adiust the briahtness and contrast until it is clear.

然后点击第2个mark点,在缩略图上找到第2个mark点。

Then click on second mark point and find second mark point on the image.

(在缩略图上任意位置双击,相机会移动到你双击的位置)。

Double-click anywhere on pcb image,camera will move to where you double-clicked.

然后设定第2个mark点,关掉设定,

After setting the second mark,close the mark setting.

工作模式里面的新建模式完成。

The new mode in the working mode is completed.

3.各类元件的编辑

3.EDITING OF VARIOUS COMPONENTS

新建模式完成后开始编辑元件

Edit the component after the new mode is completed.

首先打开工作模式中的“编辑模式”,进来后把FOV中心去掉

First open the “Teach Mode”in working mode and remove tick on “FOV center”.

左边图像放至最大,右边缩略图也要放大,以便看清小拼板上的元件。

The image on the left is FOV image,and the PCB image is on the right.

然后开始画元器件。

Then start drawing components.

电阻就选电阻组合框,点击“电阻”

Click “R”to select “Resistance”.

从本体一个角按住鼠标左键画到另外一个角,

Press and hold the left mouse button from one corner of the body to another,

会自动生成焊盘框,丝印框,还有本体框。

The pad cell,silk screen cell,and body cell will be automatically generated.

画好之后,调整每个框的大小直至合适,

After drawing,adjust the size of each cell until it fits.

然后选定元件,右键选“元件入库”

Then select the component,right-click and select “Ins.Comp to Lib”.

输入元件名称,也可用系统默认名称,点击确定

Enter the part code,or use the system default name,click OK.

入库后,如果有相同料件

After insert into library,if you have the same component on the PCB,

可以右击画好的元件选“单点复制”,复制到相同元器件

You can right-click the drawn components and select “Copy Library”to same ones.

单击左键,直到全部复制完。鼠标在空白地方右单击一下,框会消失。

Left-click until you have copied all same components.

不同型号和不同大小的元件,按上述方法重新画框

For different models or size components,draw it as described above.

接下来做电容:

Next,make a capacitor.

点击电容,也是以本体为标准,一个角画到另外一个对角,

Click on the “C”,use the body as standard,draw one corner to diagonal.

画好会自动生成两边的焊盘框,本体框,还有中间颜色框

After drawing,the pad cells,body cell,middle color cell automatically generated.

然后把每个框大小调整合适,

Then adjust the size of each box appropriately.

右击选元件入库,

Right-click and select the component to library.

有相同电容就按上述方法复制

If the same capacitor is used,copy it according to the above method.

不同的则要另画框

If it is different,another cell is required.

接下来做二极管:

Next,make the diode:

选择二极管,也是以本体的一个角画到另外一个

Select the “D”and draw it from one corner of the body to the other.

也分为两个焊盘框,一个丝印框,一个本体框,

It is also divided into two pad cells,a silk printed cell,and a body cell,

然后把每个框的大小调到合适,然后元件入库

And then adjust the size of each cell to appropriate,then put into library.

接着做三极管:选择三角件

Then make the triode:select the “3-Lead”,

把每个框的大小调至合适,然后元件入库

Adjust the size of each box,and then put into the library.

入库后有相同三极管就用复制框,不同则另画框

Use copied box to same components,and draw new one for different ones.

然后做IC:用短路框,把所有焊脚框起来

Then IC:Use “Bridge”to draw cell on all the solder pins.

框的时候注意如果旁边有白色丝印,尽量不要框到白色丝印

If there is white silk on the PCB next to cell,Avoid to include it in the cell.

框起来后,单击进入属性界面,然后打开短路设置

After cell drawn,click to enter property screen,then open the bridge setting.

如果有引脚没有分割清楚的,

If there are pins that are not clearly divided,

可以通过调整“分割阔值“进行分割,把每个脚分割清楚

You can divide them by adjusting the “segment threshold”to divide clearly.

点击‘定义引脚”,选择一个标准焊盘,把焊盘的引脚和焊盘连锡的地方框起来,点击生成引脚。

Click “Lead Def.”,select a standard pin and draw cell on it,click “Lead Reg.

生成引脚后,每个引脚会出现一个引脚框,

After generating the pins,a pin cell will appear for each pin,

然后点确定,保存,退出。

Then click OK,save,and exit.

另外一边,用同样的方法。

On the other side of IC,use the same method.

画框的时候,这个箭头一般指向本体。

When drawing a cell,this polarity arrow generally points to the body.

如果方向不对,在这里修改。

If the polarity is wrong,modify it here.

用一个“极性框”做丝印检测框

For the silkscreen,use “PS”to draw cell,

打开属性界面,把检测方法改成OCV(默认是区域法)。

Open the properties screen,change algorithm to OCV (default is region method).

然后调整属性界面的亮度和对比度,直至丝印清楚

Then adjust the brightness and contrast of the property screen until clear.

把三个框全部选中;

Select all three cells,

选中之后右键选择“合并整体”,然后元件入库

Right-click and select “Merge Comp”,put into library.

入库后,在每一边的引脚中各选一个标准的引脚

After entering the library,select a standard pin from each side of the pins,

右键选C共享即可

Right-click and select “IC share attr”.

然后用以上方法把拼板上所有的元件做完

Then use the above method to finish all the components on the PCB.

所有元件做完后,单击“一健入库”

When all the components are done,click on “A Key in Library”,

一键入库,就是把所有没有入库的元件全部入库

Then all components not yet in library will be auto-stored into library.

入库之后把拼板复制到其他拼板

After all components within a sub-pcb are in library,copy the sub-pcb to others.

点击“全选

Click “Select All”,

鼠标放到缩略图有元器件的位置右击复制,

Mouse move to the position where there is components and right click to copy.

可复制0度和180度

Can copy 0 degrees and 180 degrees,

180度为阴阳板

180 degrees are for twin sub-pcbs with reverse orientation,

0度是没有转方向的

and zero degrees have no direction of rotation.

复制后放到其他拼板的大致位置,

After copying,place it in the approximate position of other sub-pcbs,

在左边实际图像上左击,拖住一个元器件直至移正

left-click on the actual image on the left,and drag a component until aligned.

一个复制两个,两个复制四个,四个复制八个

One copy two,two copy four,four copy eight,

复制完整个拼板后点击“路径优化”,

copy to complete all sub-pcbs and click “path optimization”,

相机的运行路线会出来

then the camera’s running route will come out.

然后,再看元器件是否有复制偏移的

And then check if all components are at accurate position

如果有偏移可逐个将相机移到FOV中心点

if there is an offset,move the camera one by one to the FOV center point,

按快捷键“F8进行元件定位,

and press the shortcut key “F8″to align the component position.

然后点文件保存,元件编辑完成

Then click the file to save and the component editing is completed.

4.各种误报的调试

4.DEBUGGING OF VARIOUS FALSE ALARMS

程序编辑完之后开始程序调试

After the program is edited,the program debugging is started.

在工作模式里选择“检测模式,进入检测模式界面

Select “Auto Mode”in the work mode,enter the auto mode interface,

把“调试模式”勾上,然后点击开始检测。

tick “Debug”,and then click to start inspection.

检测完成后,轨道会退出来,然后误报都会显示出来

After the test is completed.the track will exit and then Ng result displaved

左上角这个位置是元件在这个缩略图的位置

The upper left corner is the position of the component in the PCB image,

右上角这个图形是放大的图像

and the image in the upper right corner is an enlarged FOV image,

有显示是哪个料

it is to show much detail for each NG component.

还有这个位置,显示元件的注册图形

There is also a window where the registered image of the component is displayed.

这里是这个元件检测的实际图形

Here is the actual pattern for this component inspection.

我们对元件单个框位置逐个调试

We debug the components one by one.

首先我们看它的检测方法,这里有显示检测方法

First we look at its algorithm method

检测方法一般分为区域法,OCV,颜色提取和C短路

Algorithm are generally divided into Region,OCV,Color extraction and Bridge.

这里有显示标准值,这里显示它的实际检测值

There are standard values displayed here,its actual value also displayed here

这里显示误报数量,

the number of NG components is displayed here,

这里显示添加图片的个数。

and the number of group count is displayed here.

区域法和OCV属于图像对比,

The Region and OCV belong to image comparison,

就是以做好程序的图像和现在扫描的图像进行对比

which is to compare the image of the program defined with the image scanned now

取其相似度

and take the similarity.

相似度达到82%是0K的达不到即判为NG。

It is OK to reach 82%similarity,and it is judged as NG if not reach.

调试方法就是把一个好的对比图像添加进去,点击添加组

One debugging method is to add a good similar image,and click “Add Group

移正后点确定

After correct the position,click to confirm.

里面就有两个对比图像,

Then there will be multiple similar images for this component cell.

只要其中有一个相似度达到设定值就通过,不会再误报。

As long as one of the similarities reaches the set value,it will pass.

添加之后点击文件属性,查看所添加的图片

After adding group,click on the property to view the added picture.

这里2-1,第1个不可删除

Here 2-1,the first one cannot be deleted,

它是最开始做的原始图像,

it is the original image made in the beginning.

从第2个开始可以删除,有错误添加的也可以删除

You can delete added-group from the second one if it is added by mistake.

这里可以修改它的相似度

Here you can modify its similarity.

相似度越高,检测越精准,

The higher similarity,the more accurate inspection,

反之误报越高。

On the contrary,the higher false NG warning.

也可根据元器件的实际情况去设定基准值

Reference value can also be set according to actual conditions of components.

一般默认80%左右。

Generally,the default value is about 80%.

还有颜色提取算法,它不是图像对比

There is also color extraction algorithm,which is not on image comparison.

要抽取这个框,

To extract this cell,

焊盘里面的蓝色占整个框的比例,

the blue pixels in the pad takes up the proportion of the entire cell,

设为标准83%~100%是0K的。

for this case,we set the standard 83%to 100%.

但是实际检测结果只才71%

However,the actual result is only 71%.

这里不可以添加图片,添动加图片没有任何作用,

You cannot add pictures for this algorithm,adding pictures has no effect.

只能修改里面的元件参数,

You can only modify the component parameters inside,

把这个标准降低,把83降到71以下,就不会再误报出来。

lower this standard,reduce 83 to below 71,and no more false NG will be reported.

点击元件属性,选颜色提取,

Click the component properties,select color extraction,

设定合格值标准,降低合格值标准到70%以下,就0K。

set the qualified value standard,reduce the standard to below 70%,then OK.

一般焊盘的标准值设置不要低于40%,

The standard value of the general pad should not be lower than 40%.

设的越高越精准,误报也越高。这是颜色提取的调试方法

The hiaher the settina.the more accurate.and the hiaher false Ng alarm

下一个用同样的方法进行调试。调试完几个误报后可以重新测试一下。

After debugging several NG,you can retest.

再调试,按回车键,再点开始。重新检测,再进行调试。

Click Start to retest and debug again.

如果元件框有偏移

If the component cell has offset,

可以在这里通过上下左右的箭头进行微调,

you can use the up,down,left,and right arrows to make fine adjustments here.

这种三极管,图像较为模糊的,

For this triode,the image is blurred,

可以在元件属性里修改为均值,

It can be modified to mean option in the element properties.

把红色光源去掉,然后调整亮度,直至清晰为止,

Remove the red light source and adjust brightness and contrast until it is clear.

这种二极管也可以选择用均值把红光去掉,

This diode can also choose to remove the red light with the mean option,

把亮度调清晰,然后再添加。

adjust the brightness clearly.

一般图像如果比较模糊,都可以用均值。

In general,if the image is blurred,you can use the mean option.

把红光去掉,通过亮度和对比度把图像调清楚,

Remove the red light,adjust the image clearly by brightness and contrast,

或者稍微降低图片的基准值,降低相似度进行调试

or slightly reduce the reference value of the picture to reduce the similarity for debugging.

这块调试完成后再换一块板,继续调试。

After this debug on one PCB is completed,change another PCB board to continue.

添加图片需要注意,不良图片或近似不良的图片不要添加,

Note that when adding component pictures,do not add bad pictures or near bad ones

否则会导致真正的不良检测不出来。

otherwise the real bad component will not be detected.

调试几块板,直至结果稳定。

In this way,debug several boards until the results are stable.

调试的板越多,误差越小,结果越稳定。

The more boards you debug,the less error and more stable the result obtained.

至此程序调试完成。

So far,the program debugging is completed.

5.PCB板正式检测

5.PCB board FORMAL INSPECTION

误报调试完成后就开始正式检测。

After the debugging is completed,the formal inspection will begin.

在检测模式界面,去掉“调试模式”的勾选

In the auto mode screen,clear the checkbox of Debug,

然后点击开始,即开始检测。

and then click Start to start the inspection.

检测完成后PCB板即回到待检位置。

After the inspection completed,PCB returns to the position to be inspected.

查看检测结果,用键盘的上下键逐个查看,

Use the up and down keys on keyboard to view inspection result one by one.

这里是注册图像

Here is the registered image.

如果检测图像没有问题,就直接点下一个。

Review to confirm if it is really a NG problem,then click the next one.

这个是错件。

this is the “wrong component”.

这个是少件,

This is a “missing component”,

所有误报查看完成后按回车键,然后换一块板。

After confirming all false NG,press the Enter key,then change another board.

按下机器的开始按钮,或键盘空格键,开始检测。

Press machine’s start button or keyboard space bar to start inspection on new PCB.

检测完成可以再换一块板检测

After the test is completed,you can replace the test with another board.

在检测的同时查看上一块板的误报。

When second board in process of inspection,we check false alarm of previous board.

按回车键会回到下一块板的检测界面,可以这样循环检测。

Pressing the Enter key will return to the inspection screen of the next board.

6.设置界面的介绍

6.INTRODUCTION OF SETTING INTERFACE

机器按键的介绍:

Let’s have an introduction of the machine keys:

这个是急停键,

This is the emergency stop button.

出现紧急情况可按下急停

We can press emergency to stop inspection in an emergency

这个是加载键

This is the load key.

复位键可使轨道回到待检位置。

The reset button returns the track to the position to be checked.

检测过程中如果按下停止键,机器会停止检测。

If the stop button is pressed during test,machine will stop the test.

按开始键,机器开始检测,

Press the start key,the machine starts the test,

键盘的空格键也是检测的快捷键。

and the space bar on the keyboard is also a shortcut for testing.

系统设置的介绍:

Introduction to system settings:

第1个,系统构成

The first is the system configuration.

这里是板的左下角位置的设定。

Here is the setting of the bottom left corner of the board.

在新建模式里点击左下角位置,

Go to the new mode,click the lower left corner position.

如果左下角位置有偏移,把相机位置移正。

If the lower left corner position has offset,move the camera to right position.

点击左偏移量,读取位置参数

Click “cur.Pos”by the “left offset”to set the position,

即当前位置的坐标,然后保存

that is,the coordinates of the current position,and save it.

这里是相机,FOV的大小

Here is the camera,the size of the FOV,

即相机运算的像素尺寸为1800*1800

that is,the pixel size of the camera operation is 1800 1800.

这个是用户管理,修改登录密码

This is user management,modify the login password,

在这里修改,这是创建维护

modify it here,this is the creation and maintenance.

光源的校正:相机亮度调节,

Calibration of light source:camera brightness adjustment,

通常每个月需调节一次亮度。

usually need to adjust the brightness once a month.

首先将色卡放轨道上夹好

First clip the color card on the track,

在‘系统构成界面把F0V从1800×1800改到1000×1000,然后保存

change FOV from 1800*1800 to 1000*1000 on “system Configuration”screen,then save.

再把软件退出来重新登陆。

Exit the software and log in again,

修改FOV的大小需要重启软件才会生效。

as modifying the FOV size requires restarting the software to take effect.

打开工作模式的新建模式

Open the new mode of the working mode,

把相机完全移到色卡上面,然后点开亮度调节

move camera to be fully within the color card,then click brightness adjustment.

打开亮度调节界面,点击导入默认值,

Open the “lllum control”interface,click on the ref 1,

将红绿蓝三种光源按

drag to adjust the red,green and blue light sources according to result brightness

红115、绿145,蓝150调到正负3以内。

red 115,green 145,blue 150,difference should be within 3.

调完后保存为默认值,然后退出来。

Save as default,and then exit.

再在‘系统构成’里把相机尺寸改回1800×1800

Then change the camera size back to 1800*1800 in “system Configuration”

保存退出并重启软件即可

save and exit and restart the software structure.

光源调试完成

The illum control setting is completed.

修改默认值:

Modify the default value,in teach mode,

打开注册默认值的设置,在这里设置每一个框.

open the “set default value of registration

区域法的原始默认值可根据实际情况做修改。

Default value of region algorithm can be modified according to actual requirement

IC短路的设置

The setting of the IC bridging,

搜索范围的大小,这是颜色提取。

the size of the search range,this is the color extraction.

各种框的运算方法,

The calculation methods of various cells should be debugged

要根据实际情况去调试

according to the actual situation.

mark点在这里修改

The mark point is modified here.

当mark点无法识别时,可以在这里修改其他的mark。

When the mark point is not recognized,you can modify other marks here.

运算方法的介绍:

Introduction to the calculation algorithm:

我们点击每个框时都会显示框的属性,

When we click on each cell,the properties of the cell are displayed.

这里有各种算法及其合格标准值

Here are various algorithms and their qualified standard values.

通常用到的有区域法有颜色提取,1C短路以及0CV等4种常用算法。

There are four commonly used algorithms:color extraction,bridge and OCV.

首先区域法:一般适用于本体检测

First of all,the region algorithm is generally suitable for ontology detection

其原理就是图像对比。

and its principle is image comparison.

以最开始做的图形为标准

Take the figure made at the beginning as the standard,

后面检测到的图形与这个标准图形做对比

compare the figure inspected later with this standard figure,

然后取其合格相似度

and then take the qualified similarity.

相似度达到设定的标准值为OK,达不到即为NG,

If similarity reaches the set standard value,it is OK,if not,it is NG.

标准值可以根据实际情况去设定。

The standard value can be set according to the actual situation.

通常小的元件标准值需要设得稍高一些

Generally,the standard value of small components needs to be set a little higher,

大的元件和模糊的元件可以设低一点。

and large components and fuzzy components can be set lower.

模糊图像可以用均值把红光去掉,调试亮度进行测试

Blurred image we used to remove the red light and debug the brightness for testing.

OCV算法:一般用于测试丝印

OCV algorithm:generally used for testing silk screen,

它也属于图像对比,但只是对比字符部分

it also belongs to image comparison,but only compares the character part.

可以通过分割法调整图形的清晰度。

You can adjust the sharpness of the graphics by segmentation.

颜色提取算法:打开颜色提取设置,

Color extraction algorithm:open the color extraction settings,

系统默认出蓝色,因锡是蓝色,也可以设置别的颜色。

the system defaults to blue,because tin is blue,can also set other colors.

色调代表你抽取的某一个色调

The hue represents a certain hue that you have extracted.

可以抽取红色,也可以是其它各种颜色。

You can extract red or other colors.

亮度代表单个色调的亮度

Lightness represents the brightness of a single hue.

饱和度可全部调到最大

Saturation can be fully adjusted to the maximum.

在下面调整颜色比例

Adjust the color ratio below.

可根据实际情况设定,

It can be set according to the actual situation.

建议焊点的蓝色比例不要低于40%。

It is recommended that the blue ratio of solder joints not be less than 40%.

最后是IC短路算法:

Finally,the IC short circuit algorithm:

打开短路设置,调整分割阈值把引脚分开,

Open the short circuit setting,adjust the split threshold to separate the pins,

系统会计算出引脚的数量及每个的长度、宽度,再定义引脚

system will calculate the number of pins,length,width of each,then defines pins.

7.在线800与离线880的区别

阿里云盘的易科讯aoi编程视频教程

「aoi编程视频教程」https://www.aliyundrive.com/s/UnRsK5qzKSN

百度网盘的易科讯aoi编程视频教程

链接: https://pan.baidu.com/s/1NRndXmWRE9PaP7Rzw84UtA?pwd=b59u 提取码: b59u